Modern unibody car designs, like Mercedes-Benz models, pose challenges for repair and restoration due to intricate structures and safety features. Panel sectioning techniques are crucial, enabling detached replacement of damaged sections like doors or fenders without affecting other components. This meticulous process ensures structural integrity, high-quality paint jobs, and restores vehicles to pre-incident condition, using advanced tools and strategies to navigate complex structures efficiently.

In the realm of industrial design, unibody structures offer unparalleled lightweight strength. However, their complexity poses unique challenges in manufacturing. This article explores essential panel sectioning techniques tailored for complex unibody designs. We delve into understanding the intricacies of unibody design complexities and introduce effective methods to simplify production. By implementing strategic sectioning strategies, designers can now navigate intricate forms seamlessly, revolutionizing how we approach these advanced structures.

- Understanding Unibody Design Complexities

- Introduction to Panel Sectioning Methods

- Implementing Effective Sectioning Strategies

Understanding Unibody Design Complexities

Unibody designs, prevalent in modern automobiles like Mercedes-Benz models, present unique challenges during repair and restoration processes. These intricate structures, while offering enhanced safety features, demand precision and specialized techniques for effective repairs, especially after hail damage or an accident. The unibody, comprising a continuous metal frame, requires careful manipulation to ensure structural integrity is maintained throughout the repair process, mimicking the original manufacturing quality.

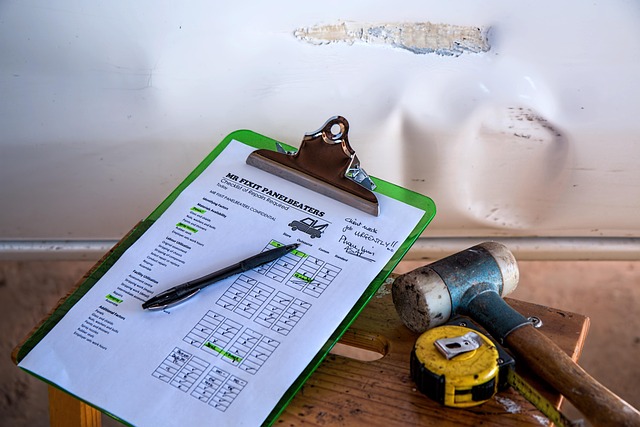

Panel sectioning techniques play a pivotal role in addressing these complexities. This method involves carefully detaching and replacing damaged sections of the unibody, such as doors or fenders, without disturbing surrounding components. It’s akin to a puzzle where each panel is meticulously fitted back together, ensuring seamless car paint services and restoring the vehicle to its pre-incident condition, much like a hail damage repair expert would undertake.

Introduction to Panel Sectioning Methods

In the realm of complex unibody designs, particularly within the automotive industry, panel sectioning techniques play a pivotal role in both manufacturing and automotive collision repair. These methods enable the precise separation and removal of specific vehicle panels for maintenance, replacement, or customization. By employing specialized tools and strategies, professionals can efficiently navigate intricate structures, ensuring minimal damage to surrounding components during tire services or automotive repair processes.

Panel sectioning techniques have evolved significantly, offering a range of options from manual cutting and rivet removal to advanced automated systems. Each method caters to different levels of complexity and precision required in modern vehicle design. Understanding these techniques is crucial for professionals in the automotive sector, as it facilitates faster turnaround times, reduces costs, and enhances the overall quality of repair or customization work, be it for original equipment manufacturers or specialized custom car builders.

Implementing Effective Sectioning Strategies

Implementing effective panel sectioning strategies is paramount for achieving precise and efficient unibody design work, particularly in complex vehicle collision repair and autobody repairs scenarios. Skilled technicians leverage specialized tools and techniques to divide the car body into manageable sections, allowing them to focus on individual components while ensuring structural integrity throughout the restoration process.

These strategic cuts facilitate access to hidden areas, streamline repairs, and minimize material waste during car body restoration. By carefully planning panel sectioning, professionals can navigate intricate curves and contours, addressing damage with accuracy and care. Such meticulous approaches not only enhance the quality of autobody repairs but also contribute to the overall longevity and aesthetic appeal of the vehicle following collision incidents.

Panel sectioning techniques offer a powerful solution for managing the complexities of unibody design. By understanding the unique challenges and implementing strategic sectioning strategies, designers can efficiently navigate intricate geometries, optimize material usage, and streamline manufacturing processes. These methods are essential tools in the modern automotive industry, enabling the creation of lightweight, efficient, and visually appealing vehicle structures.