Panel sectioning techniques are crucial for repairing and replacing unibody structures in modern vehicles, addressing their complex geometry and tight tolerances. These advanced methods involve cutting, joining, scratch repair, and precise alignment to maintain structural integrity and minimize impact during collision repairs. In luxury car manufacturing, specialized software, CAD, and FEA enable engineers to design lightweight yet sturdy structures, enhancing efficiency and streamlining production processes.

In the realm of automotive design, unibody structures offer lightweight, robust solutions, yet their complexity poses unique challenges. This article explores advanced panel sectioning techniques crucial for crafting intricate unibody designs. We delve into understanding the structural intricacies and challenges inherent in unibody constructions, followed by an introduction to strategic panel sectioning strategies. Additionally, we uncover cutting-edge methods enhancing design optimization for complex unibody components.

- Understanding Unibody Structures and Their Challenges

- Introduction to Panel Sectioning Strategies

- Advanced Techniques for Complex Design Optimization

Understanding Unibody Structures and Their Challenges

Unibody structures, a prominent design feature in modern vehicles, present both advantages and challenges when it comes to repair and maintenance. This single, integral piece that comprises the vehicle’s chassis, body, and structural components offers enhanced safety and lightweight benefits but also poses unique issues during repairs or panel replacement. The complex geometry and tight tolerances of unibody designs require precise and specialized techniques for effective panel sectioning.

Understanding how to navigate these challenges is crucial in the collision repair industry. Panel sectioning techniques play a vital role in repairing and restoring unibody structures, ensuring vehicles return to their pre-collision condition. With the right methodologies, including advanced cutting and joining processes, scratch repair, and precise alignment, collision repair centers can address damages efficiently, preserving the integrity and structural soundness of these intricate vehicle designs while minimizing the impact of a vehicle collision repair.

Introduction to Panel Sectioning Strategies

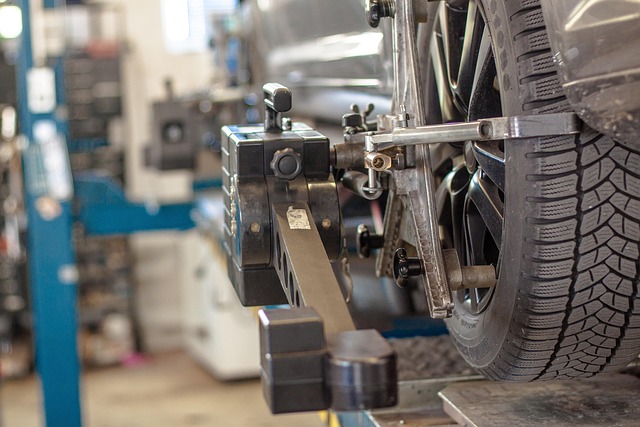

In the realm of complex unibody design, panel sectioning techniques are crucial for efficient manufacturing and repair processes. These strategies involve carefully cutting and separating sections of a vehicle’s body, enabling precise manipulation and reconstruction during both initial production and subsequent vehicle collision repair or automotive restoration endeavors. By employing sophisticated tools and methods, manufacturers can ensure structural integrity while achieving intricate designs that define modern automobiles.

Effective panel sectioning techniques play a pivotal role in streamlining vehicle repair services, allowing technicians to replace or refurbish damaged areas without compromising the overall aesthetic or structural soundness of the vehicle. This meticulous process requires a deep understanding of material properties and engineering principles, especially when dealing with advanced materials used in contemporary automotive designs.

Advanced Techniques for Complex Design Optimization

In the realm of complex unibody designs, advanced techniques for optimization are essential to achieving lightweight, sturdy structures. Panel sectioning techniques, a cutting-edge approach in auto repair services and dent repair, offer engineers unprecedented control over material distribution. By meticulously dissecting and analyzing the vehicle’s body panels, professionals can identify areas where weight reduction is feasible without compromising structural integrity—a key advantage for Mercedes Benz collision repair, among other luxury car brands.

This precise method involves using specialized software to model and simulate various panel configurations. Through computer-aided design (CAD) and finite element analysis (FEA), auto body specialists can test different scenarios, ensuring the final product meets safety standards while maximizing performance. The integration of these advanced techniques not only streamlines the manufacturing process but also enhances overall vehicle efficiency, making it a game-changer in the industry, particularly for complex automotive designs.

Panel sectioning techniques have proven invaluable in tackling the intricate design challenges posed by unibody structures. By employing advanced strategies, engineers can optimize complex designs, ensuring lightweight, robust, and efficient components for modern vehicles. These innovative methods not only streamline manufacturing processes but also enhance overall vehicle performance, making panel sectioning a key consideration in the automotive industry’s ongoing pursuit of excellence.