Panel sectioning techniques, vital for automotive technicians in car paint repair and collision restoration, demand precision balancing of structural preservation and risk mitigation. This process involves meticulous cutting and separation while avoiding adjacent panel damage or misalignment during reassembly. Safety is paramount, with specialized gear like goggles, respirators, gloves, ear protection, and reflective clothing crucial to protect technicians from hazardous materials and noise damage. Best practices include pre-work inspections, utilizing specialized tools, clear zone demarcation, and effective communication for a secure and accurate workspace.

In the realm of technical expertise, panel sectioning techniques are indispensable for technicians navigating complex tasks. This article delves into the critical safety precautions essential for professionals employing these methods. We explore the understanding and associated risks of panel sectioning, highlighting the need for specific safety gear. Furthermore, best practices and protocols are outlined to ensure safe operations, providing a comprehensive guide for technicians to mitigate hazards effectively while utilizing panel sectioning techniques.

- Understanding Panel Sectioning Techniques and Associated Risks

- Essential Safety Gear for Technicians Performing Sectioning

- Best Practices and Protocols for Safe Sectioning Operations

Understanding Panel Sectioning Techniques and Associated Risks

Panel sectioning techniques are crucial skills for technicians in the automotive industry, particularly in car paint repair and automotive collision repair. These methods involve carefully cutting and separating specific sections of a car body for repair or replacement, requiring precision and knowledge to avoid risks. The process can be intricate, especially when dealing with complex car body structures, and improperly executed sectioning can lead to structural integrity issues and unsafe vehicles.

Associated risks include damage to surrounding panels, misalignment during reassembly, and exposure to hazardous materials like paint fumes or toxic chemicals used in previous repairs. Technicians must be well-versed in various panel sectioning techniques to navigate these challenges effectively. Understanding the nuances of car body repair, including the interplay between different sections, is vital for ensuring the safety and quality of vehicles undergoing automotive collision repair or car body repair processes.

Essential Safety Gear for Technicians Performing Sectioning

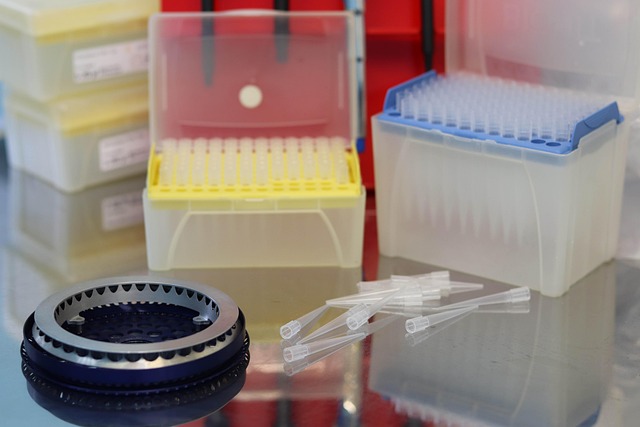

Technicians performing panel sectioning techniques require specialized safety gear to mitigate risks associated with this intricate process. Essential equipment includes high-quality protective goggles to shield against flying debris, a respirator or face mask to prevent inhalation of harmful dust and fumes, and heavy-duty work gloves designed to withstand the strain of cutting and handling vehicle panels.

Additionally, a robust set of ear protection is crucial due to the noise generated by power tools. In auto body restoration or auto collision centers, where panel sectioning often occurs, ensuring technicians wear reflective clothing becomes vital for their safety, especially in environments with heavy traffic and machinery. These measures not only protect technicians but also contribute to the overall efficiency and accuracy of vehicle bodywork processes.

Best Practices and Protocols for Safe Sectioning Operations

When performing panel sectioning techniques, technicians must adhere to strict safety protocols to prevent injuries and ensure a secure workspace. Best practices include wearing appropriate protective gear such as safety glasses, gloves, and earplugs. These precautions safeguard against flying debris, chemical exposure, and noise-related damage. Additionally, utilizing proper tools designed for panel sectioning reduces the risk of accidents.

Before initiating any car paint repair or vehicle restoration tasks, a thorough inspection of the area is crucial. Identifying potential hazards like loose wiring or structural weaknesses allows technicians to implement necessary precautions. In a vehicle body shop environment, effective communication and clear demarcation of work zones further enhance safety during panel sectioning operations.

Panel sectioning techniques are invaluable in various industries, but they come with inherent risks. By understanding these risks, investing in essential safety gear, and adhering to best practices, technicians can ensure safe and efficient operations. Implementing these precautions not only protects individuals but also enhances the quality of work, making it a crucial step for any technician employing panel sectioning techniques.