Panel sectioning techniques are crucial in automotive manufacturing, restoration, and tire services for targeted repairs and replacements. In hail damage or collision repair, precise measurements using advanced tools ensure structural integrity, efficiency, minimize waste, reduce costs, and promote sustainability. Systematic measuring boosts productivity in bodywork repair, transforming chaotic workshops into streamlined environments.

In the realm of precision manufacturing, understanding and optimizing panel sectioning techniques is paramount. This article delves into the critical role of measurement systems in enhancing these processes. From panel sectioning techniques comes the requirement for accurate measurement to ensure quality and consistency. We explore how systematic measuring improves efficiency, addressing crucial aspects like precision, material waste reduction, and consistent panel dimensions. Ultimately, this focus on measurement is a game-changer for achieving excellence in panel fabrication.

- Understanding Panel Sectioning Techniques

- The Role of Measurement in Accuracy

- Enhancing Efficiency through Systematic Measuring

Understanding Panel Sectioning Techniques

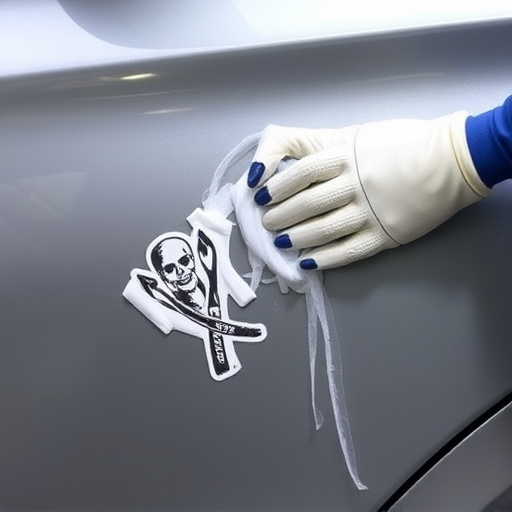

Panel sectioning techniques play a pivotal role in various industries, from automotive manufacturing to intricate car body restoration and tire services. This process involves dividing a larger panel or surface into smaller segments for specific purposes such as repairs, replacements, or modifications. Understanding these techniques is essential for ensuring precision and efficiency in auto maintenance and beyond.

By employing panel sectioning, professionals can carefully isolate problem areas without affecting surrounding components. In car body restoration, for instance, this method allows restorers to fix or replace damaged panels while preserving the original aesthetics of the vehicle. Similarly, in tire services, precise sectioning enables technicians to address issues within specific segments of a tire, extending its lifespan and enhancing performance.

The Role of Measurement in Accuracy

In the realm of panel sectioning techniques, particularly within automotive industries offering hail damage repair or vehicle collision repair services, measurement plays a pivotal role in ensuring accuracy and precision. Accurate measurements are fundamental to the success of any panel replacement or restoration process. Skewed or imprecise measurements can lead to misaligned panels, compromising the structural integrity and overall aesthetic appeal of the vehicle. By employing advanced measurement tools, technicians can swiftly and accurately assess damage, determine required repairs, and obtain precise cut lines for new panels. This meticulous approach is key to achieving seamless joins, ensuring that repaired vehicles match their pre-incident condition, both in terms of functionality and appearance.

The impact of accurate measurements extends beyond mere aesthetic restoration; it significantly influences the overall efficiency of automotive repair services. Proper measurement techniques streamline the panel sectioning process, minimizing waste and optimizing material utilization. This not only reduces costs for both repair shops and vehicle owners but also contributes to a more sustainable automotive industry by minimizing material wastage. In essence, precise measurements are not merely an aspect of quality control; they are a cornerstone for efficient, effective, and reliable hail damage repair or vehicle collision repair services.

Enhancing Efficiency through Systematic Measuring

In the realm of panel sectioning techniques, enhancing efficiency is paramount for achieving precision and quality in vehicle repair, particularly concerning vehicle bodywork or autobody repairs. Systematic measuring plays a pivotal role in this process by ensuring every cut is accurate and aligned. Advanced measurement tools enable technicians to quickly capture complex geometry data, streamlining the disassembly and reassembly processes. This not only reduces labor hours but also minimizes the risk of errors that can lead to costly rework.

By adopting systematic measuring practices, workshop environments transform from labyrinthine to streamlined. Technicians can efficiently navigate intricate panel structures, ensuring each component is carefully considered before removal or modification. This meticulous approach translates into improved overall productivity in both small-scale and large-scale vehicle repair operations, making it a cornerstone for any successful autobody repairs endeavor.

Panel sectioning techniques, when combined with precise measuring systems, offer a powerful approach for enhancing accuracy and efficiency in manufacturing. By understanding the intricacies of these techniques and leveraging measurements, manufacturers can ensure consistent quality, minimize errors, and optimize production workflows. This, in turn, leads to cost savings and improved product consistency, making it an indispensable practice in modern industrial processes.